Inevitable TechnologiesVisual Concepts and System Architecture for Controlled Environment Agriculture (CEA)

OVERVIEW

What does the future of plant propagation and food production look like for a world facing climate uncertainty and an ever-growing population? Many companies are already imagining solutions for what this future might be, but for Mighty’s client, Inevitable Technologies, initial forays into CEA solutions for everyday produce unearthed an opportunity to pivot. What if they focused primarily on the start of the propagation process (germinating and sprouting the seed) to create an automated and sustainable system that would set customers up for optimal growth, literally.

The seed—this time of an idea—was planted.

A key strength of Mighty Studios is the ability to jump into a project mid-innovation and add an extra layer of strategic and creative brainpower to help guide a product or idea to the next phase. While Inevitable Technologies had already developed an indoor automated grow ecosystem, it had focused on the full growth cycle—from seed to mature plant. For the next phase, they called on Mighty to take the idea and evolve it, generating workable concepts and assets that painted a picture of what a new automated system could look like, but focusing solely on the seed/sprouting phase.

The challenge? The system would need to be scalable, easily deployable, use space efficiently for maximum production, and above all, grow healthy, high-quality plants.

The result and vision provided by Mighty was a robust system architecture for revolutionizing food production, coupled with powerful visual assets to inspire potential investors and help make this vision a reality.

INSIGHTS

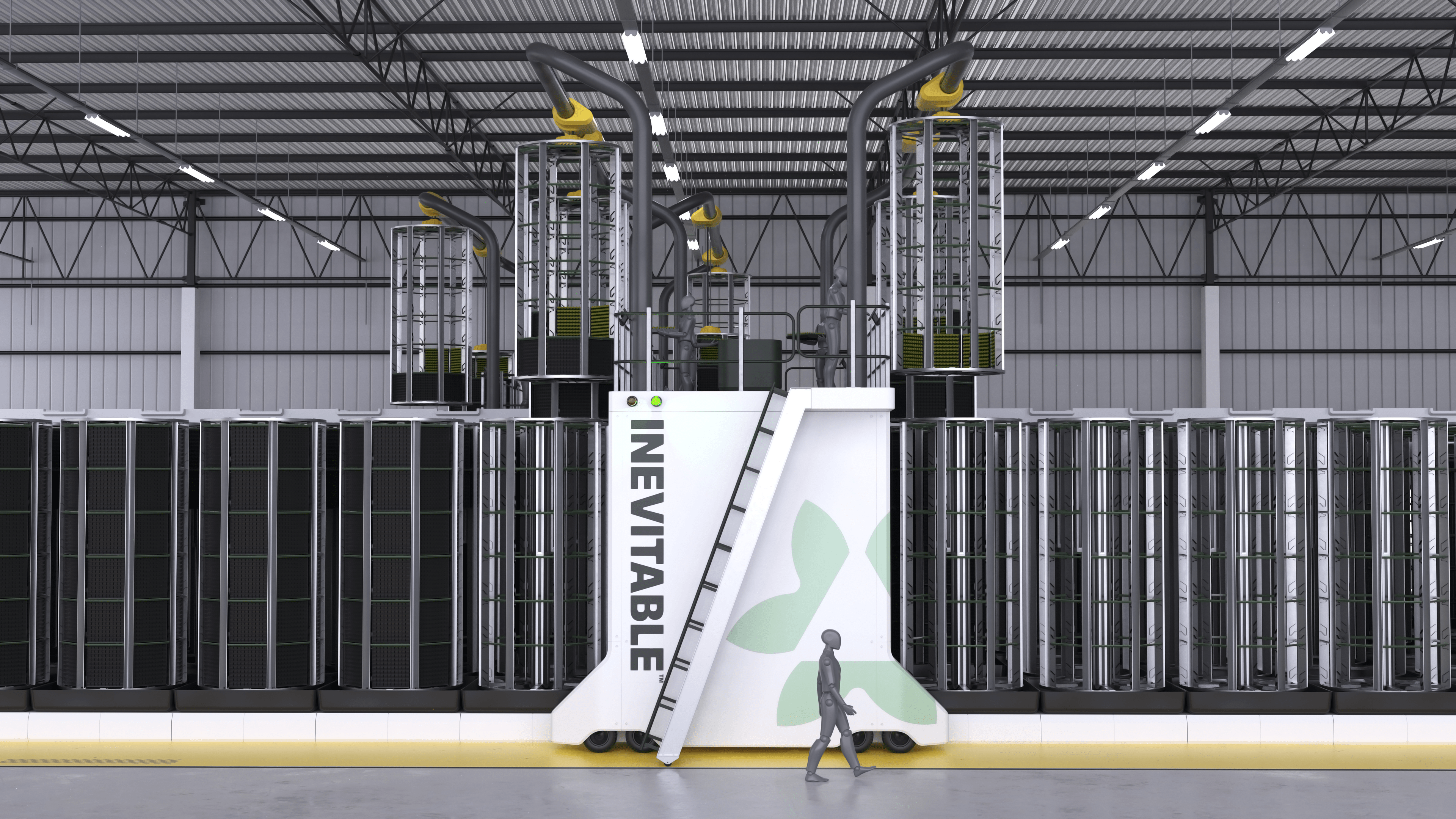

The 10,000 ft. view of Inevitable Technologies’ mission is to create a sustainable and scalable food production solution that will operate within the parameters of a climate in flux and a growing population. The vision: deploy warehouses containing a climate-controlled grow system, optimized for vegetables and produce, into non-arable areas of the United States to sprout seeds to be sold and shipped nationwide.

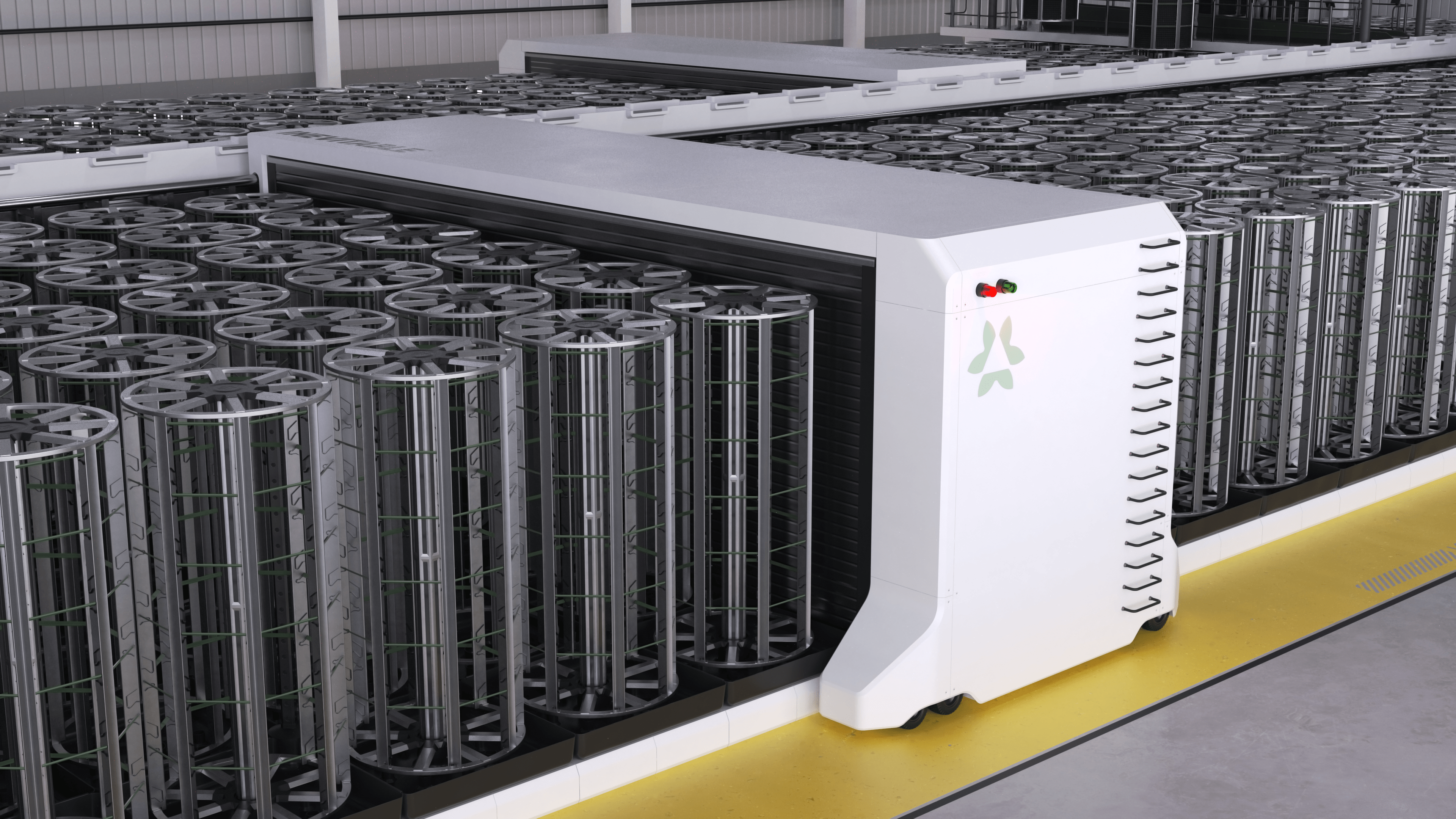

The first iteration of their grow house solution was an automated system that used AGVs to move flat, plant-filled trays around a warehouse to different stations, depending on their growth stage—to light or water, for example. While a workable way to grow and harvest plants, it was not the most efficient way to utilize the space or resources.

With their new goal of focusing on the seed-to-sprout stage, the challenge for Mighty was to determine the best way to maximize the footprint of a warehouse and grow the most plants within that space. The team got to work brainstorming ideas for an entirely new system, taking on both the visual aesthetic and deployment concepts.

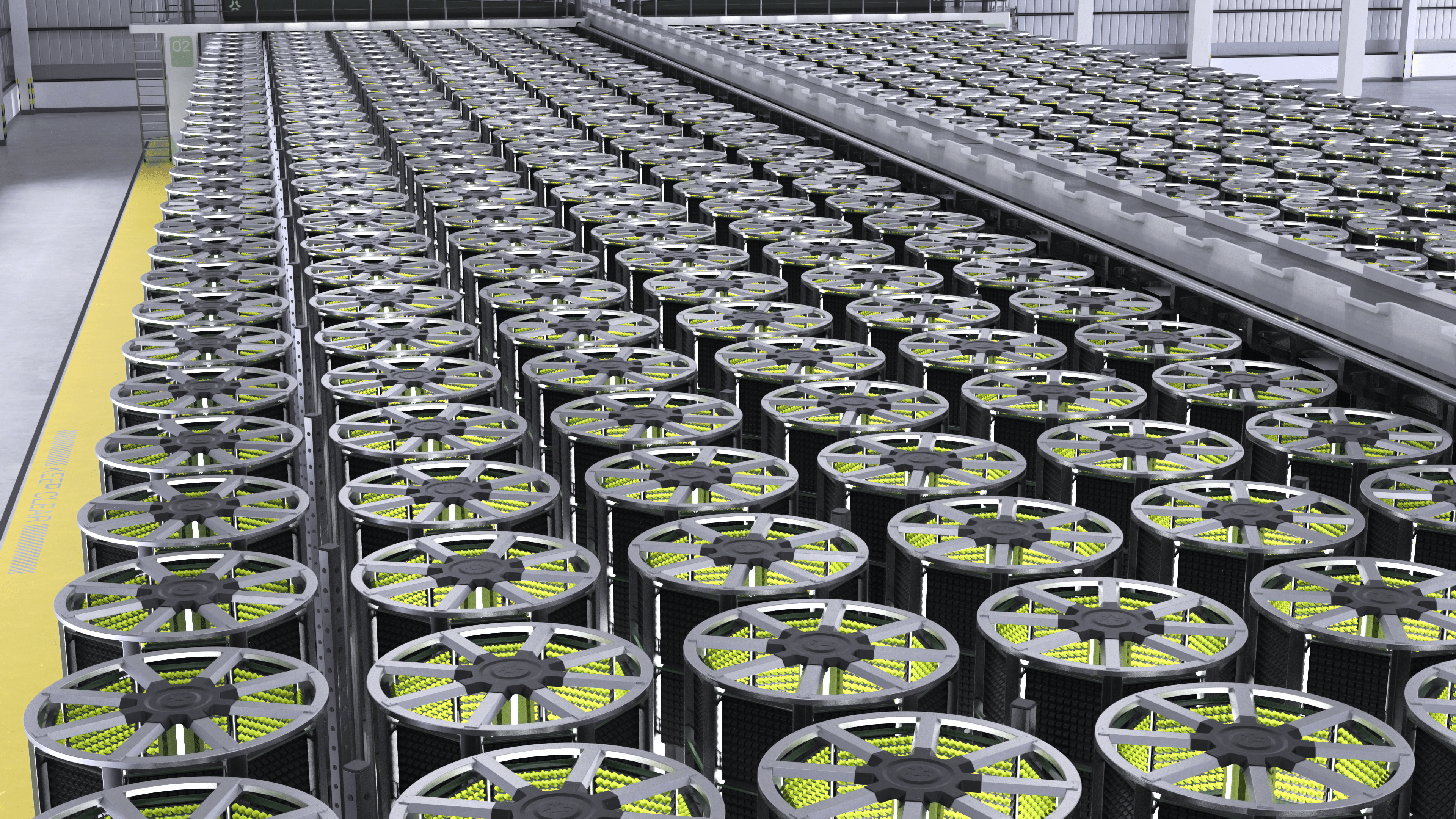

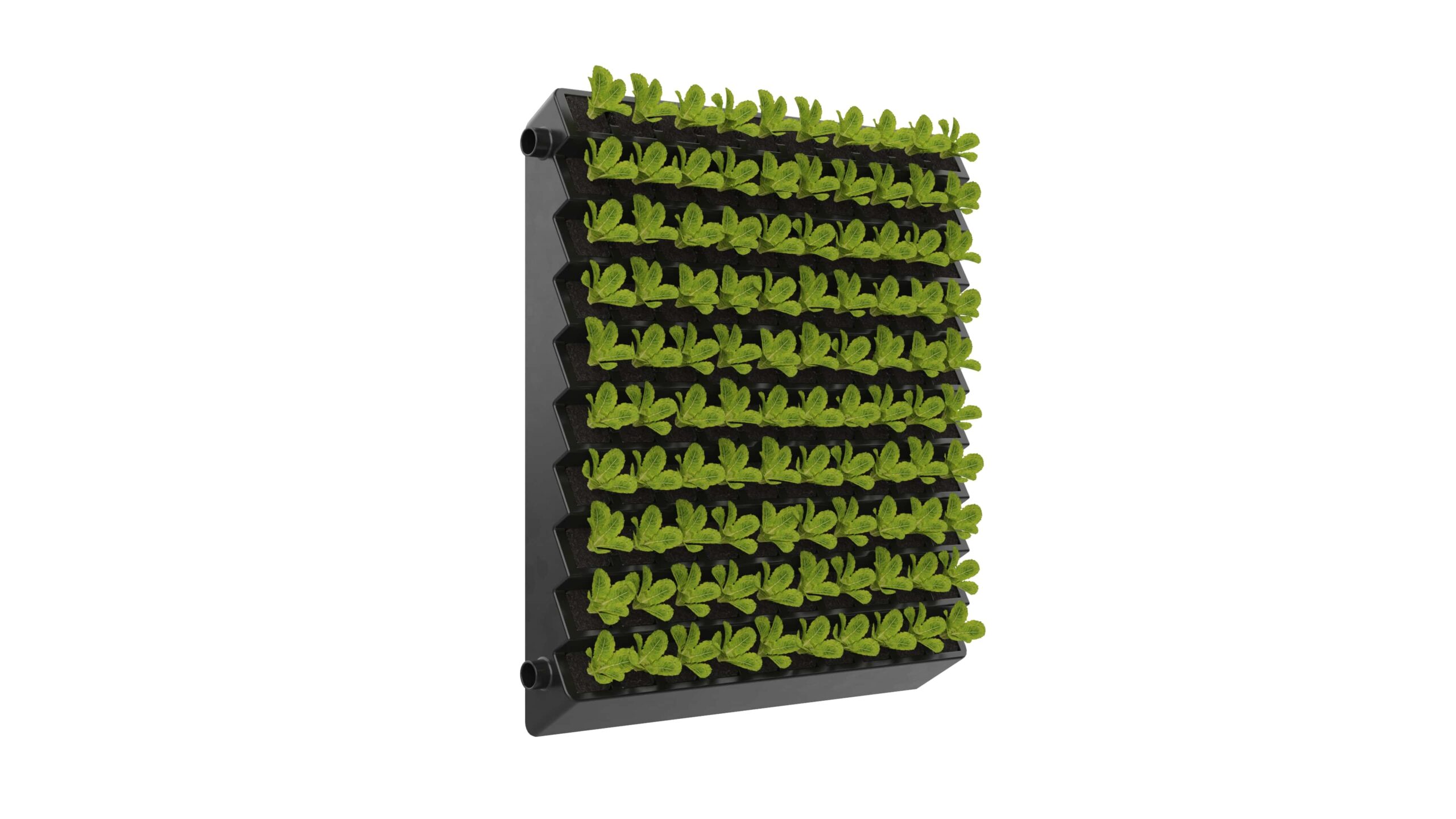

As problem solvers, not just of business objectives but of design functionality, Mighty’s first breakthrough began with a simple idea: what if the trays did not lay out flat on a space-hogging table? What if they rolled each flat tray into a column and stood it up, creating a sort of standalone tower of sprouting seeds? This column could then become like a cartridge to be loaded in and out of an array of cartridges—like rows in a field—each at different stages of growth.

It was a eureka moment. With the flats of seedlings—each embedded in a plug of nutrient-rich soil comprised of fiber and compacted dirt, with about 4,800 per column—now standing vertical, the next challenge to be solved was how to keep these plants alive and thriving.

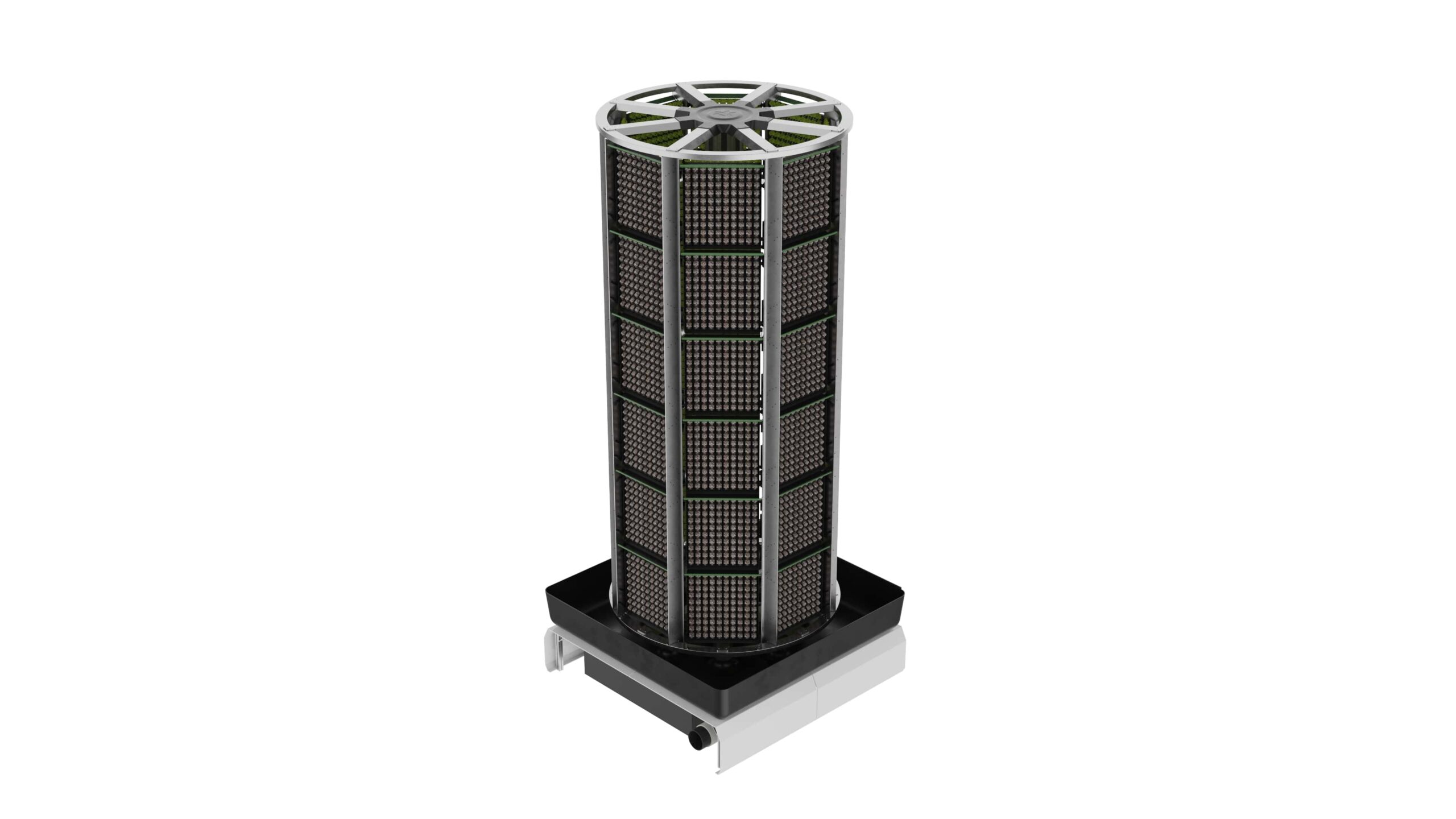

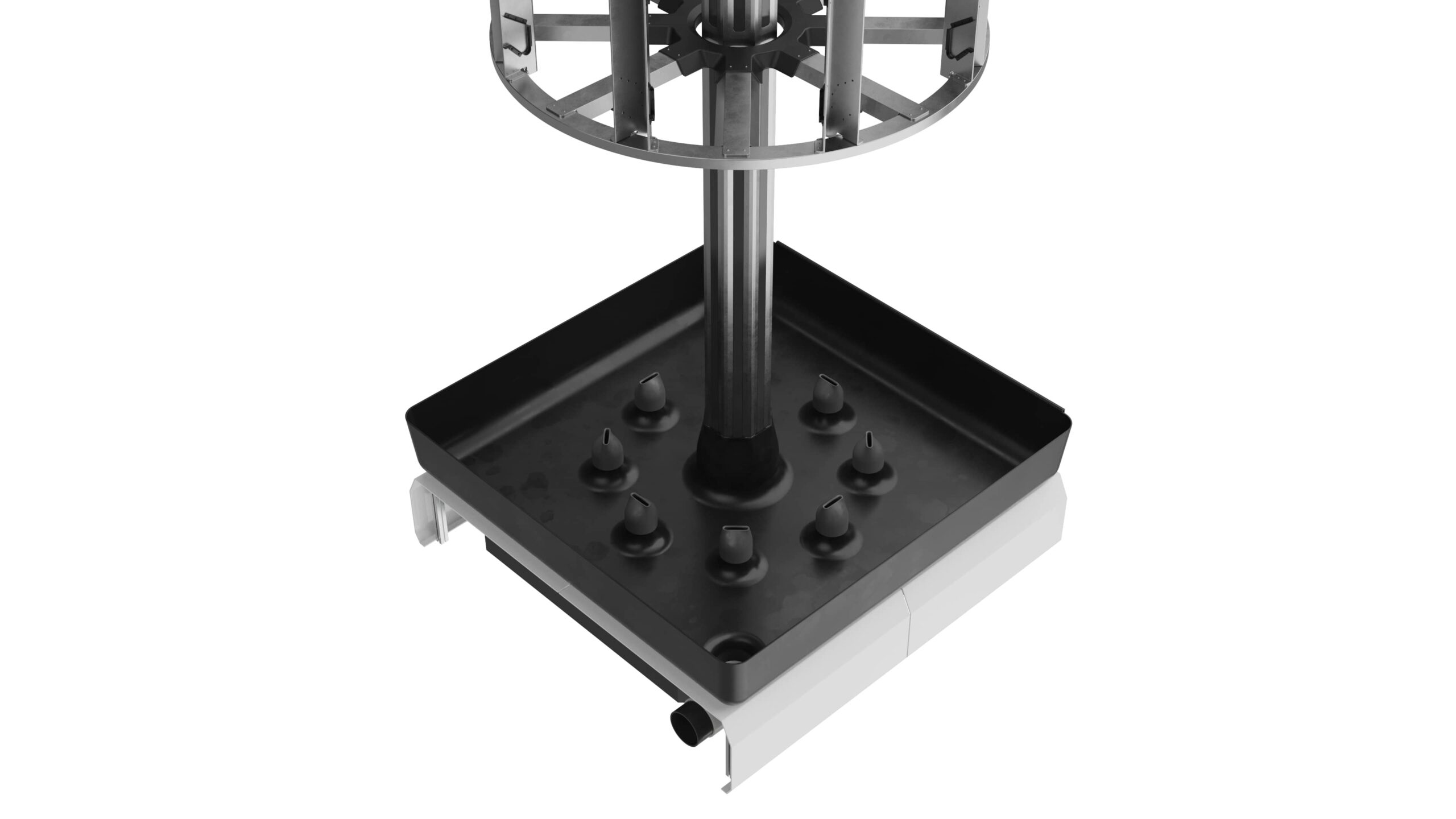

Plants are simple. They need light, water, and nutrients. By creating a cylinder of grow tray seedlings that curved around a light source, the seedlings had full access to uniform, artificial sunlight. In terms of a watering system, with the backs of the trays exposed on the cylinder exterior, Mighty developed a watering system between each to spray the backside of the flats. The columns would then rotate for more even water distribution. Run off from this watering process would be collected, filtered, re-conditioned with nutrients, and then reintroduced to the system.

Humidity and temperature fluctuations were also considered. With each column standing at 4.25 meters tall, the gradient of temperatures would vary from top to bottom. Mighty designed an airflow system to push air from the bottom up to keep circulation constant and create the perfect environment for the seedlings to thrive.

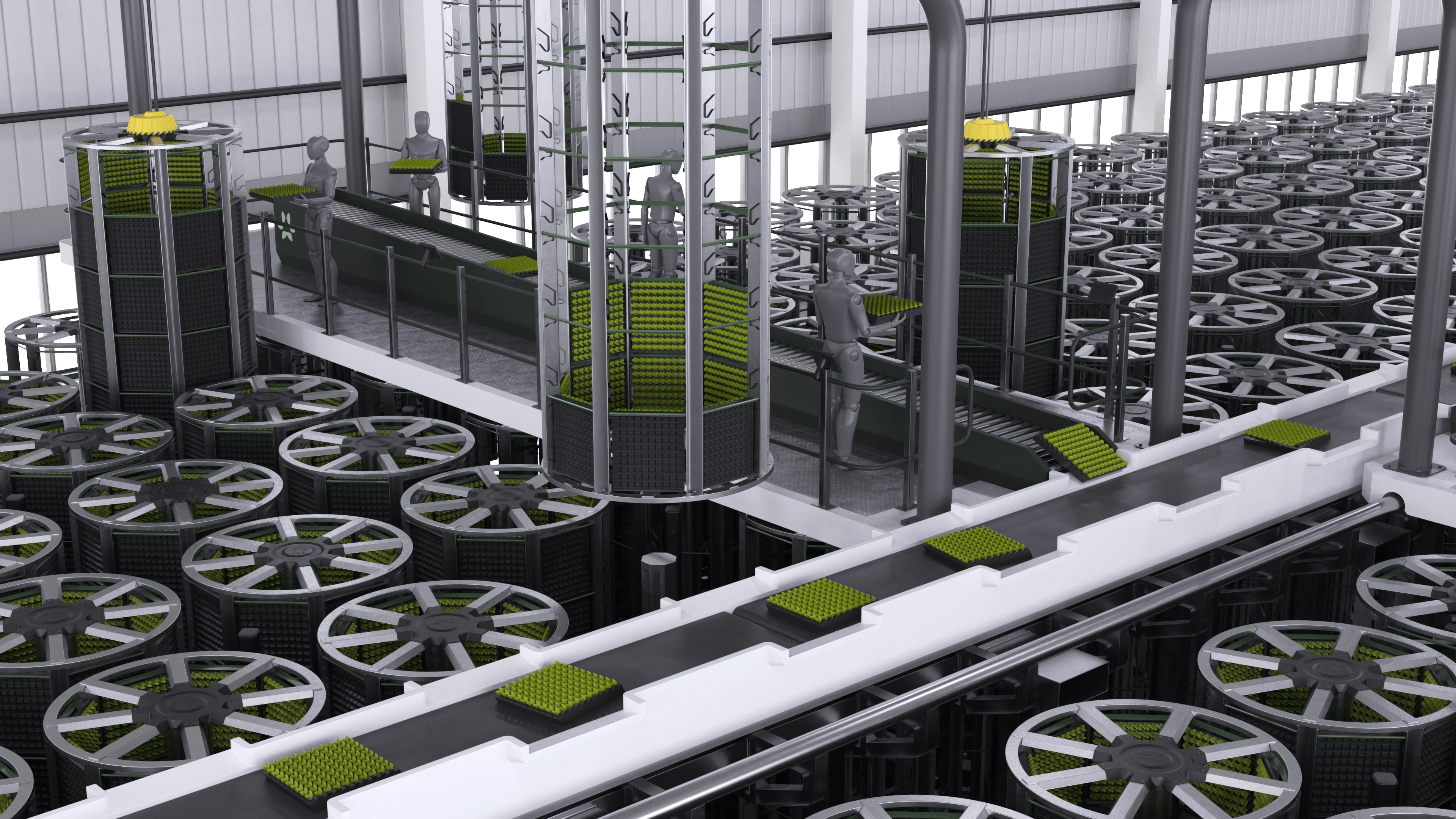

Along with environmental considerations, Mighty tackled the day-to-day mechanics of how the system would run. From planting to harvest and replanting for the next round, how would the system function, and at what points would humans interact? The solution was a synergy of automated processes with human involvement where needed. With columns of plants, each at a different stage of growth, the multi-purpose gantry played an essential role.

Come harvest, the gantry would move to a ready row, positioning itself above a column to lift it out of the grow phase. Once lifted, the flats containing the plants would be pulled off by humans, laid flat on a conveyor, moved to the loading dock, put on a refrigerated truck, and transported to the end user.

The entire system could also be cleaned, again by using the gantry. The vision for this process would be to position the gantry over a section of 12 now-harvested columns. A garage-style door would slide down, and the isolated section would then be pressure-washed and sterilized, ready for the next batch of seeds to be added to the columns.

Fully scalable, Mighty devised a system architecture that could be deployed as a quadrant of four columns, or in any configuration that would fit the end-customer’s needs, from a small business space to a large, commercial warehouse. This system allows for better utilization of any warehouse footprint and creates a high-density grow space. It also gives the ability to create a continuous rotation of semi-mature to mature plants ready to leave the warehouse, primed for the next step of the growth cycle.

The Inevitable Technologies project illustrates the value Mighty Studios brings to the table and was a true blend of everything this small but powerful studio excels at: providing conceptual firepower that takes into consideration all creative challenges and issues, crosschecked against business requirements and needs. With concept and design in hand, Inevitable Technologies can now take that packaged vision and move on to next steps and are currently prototyping against the designs and solutions Mighty developed for this assignment.

The future of food production may just be around the corner—or in a 4.25-meter-high rotating tower of seeds—near you.