UC BerkeleyTMS Coil Robot Development

OVERVIEW

“There must be a better way.”

This statement, found so often at the first spark of innovation, forms the foundation of many of Mighty Studio’s engineering assignments. In the case of UC Berkeley’s TMS Coil Robot project, the “better way” led to the from-scratch invention of all-new parts and functionality to make this device real.

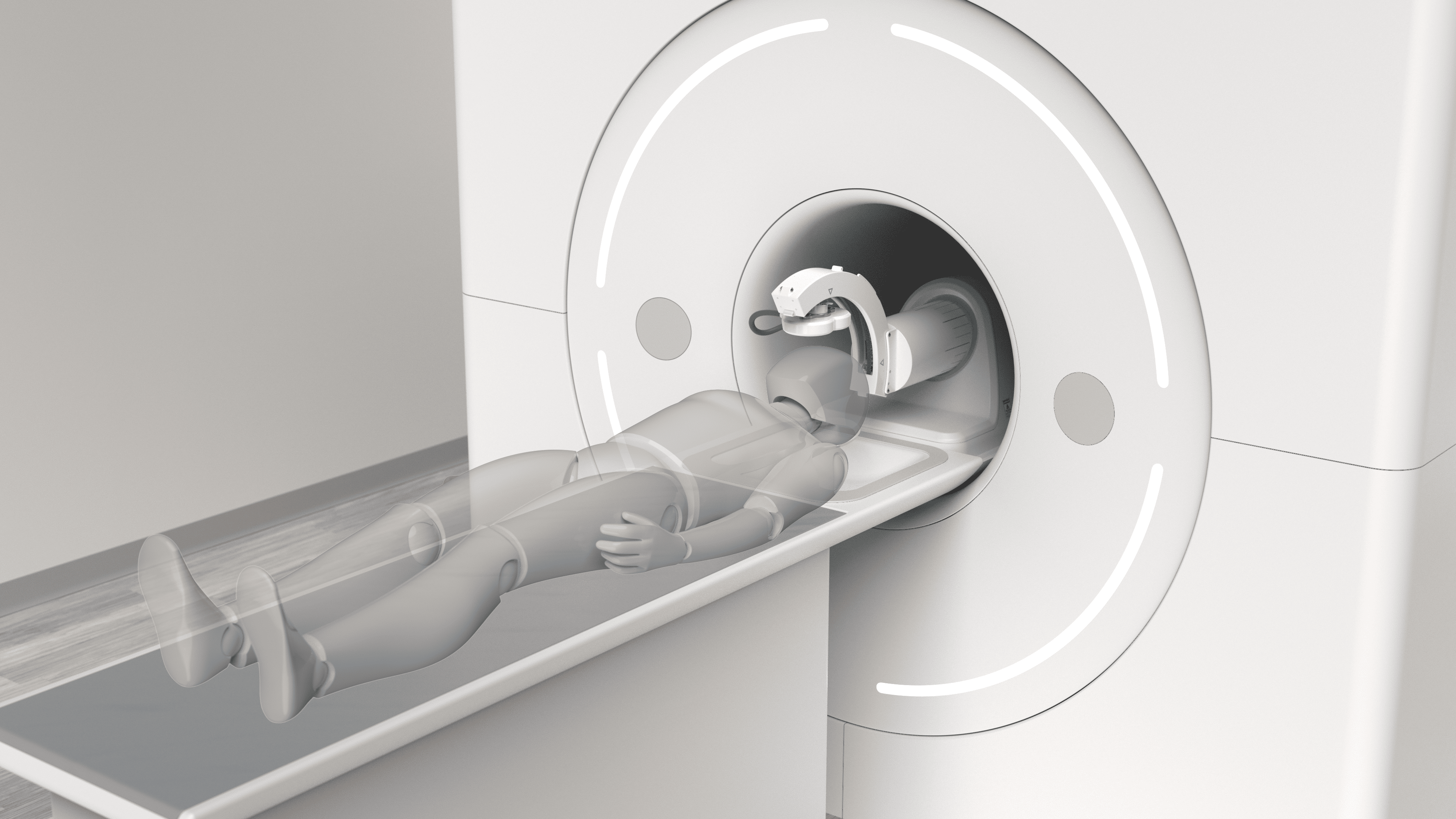

TMS—short for Transcranial Magnetic Stimulation—is a non-invasive procedure used to treat brain-related conditions such as migraines, depression and certain types of seizures. In its current application, physicians locate the general area of the patient’s brain containing an anomaly, position a TMS coil at the site, and “zap” the area with a magnetic pulse to stimulate activity and treat the problem.

While effective, the ability to locate the anomaly more precisely using an MRI machine would improve results. For this engagement, the client challenged Mighty to create an armature that allowed for the TMS coil to function inside the chamber of an MRI, an environment notorious for being hostile to devices fabricated from metal materials.

The desired solution also needed to be adjustable, giving physicians the flexibility to administer the treatment to a precise location on the patient’s head while the patient was still in the chamber.

With the main challenge identified—to create a robot armature that was adjustable by degrees, in all directions, and would function within an MRI machine, both in terms of construction materials and size constraints—Mighty delivered a beta device with the potential to revolutionize the treatment of brain-related disorders using existing TMS coil technology.

From start to finish, the only thing that could be described as off-the-shelf for this project was the TMS coil itself.

INSIGHTS

As with most things groundbreaking, the task sounds simple, but the solution is not. The biggest issue Mighty faced involved the materials from which their solution would be fabricated. Knowing that introducing a metallic, robotic armature inside an MRI tube would lead to catastrophe, most parts and pieces would need to be engineered in MRI-safe polycarbonate, with a few small titanium components.

Along with material considerations, with the TMS coil mounted to the robotic arm, the entire mechanism would need to fit inside a standard MRI bore, plus be easily rotated and moved around the human head to be positioned precisely at a treatment site.

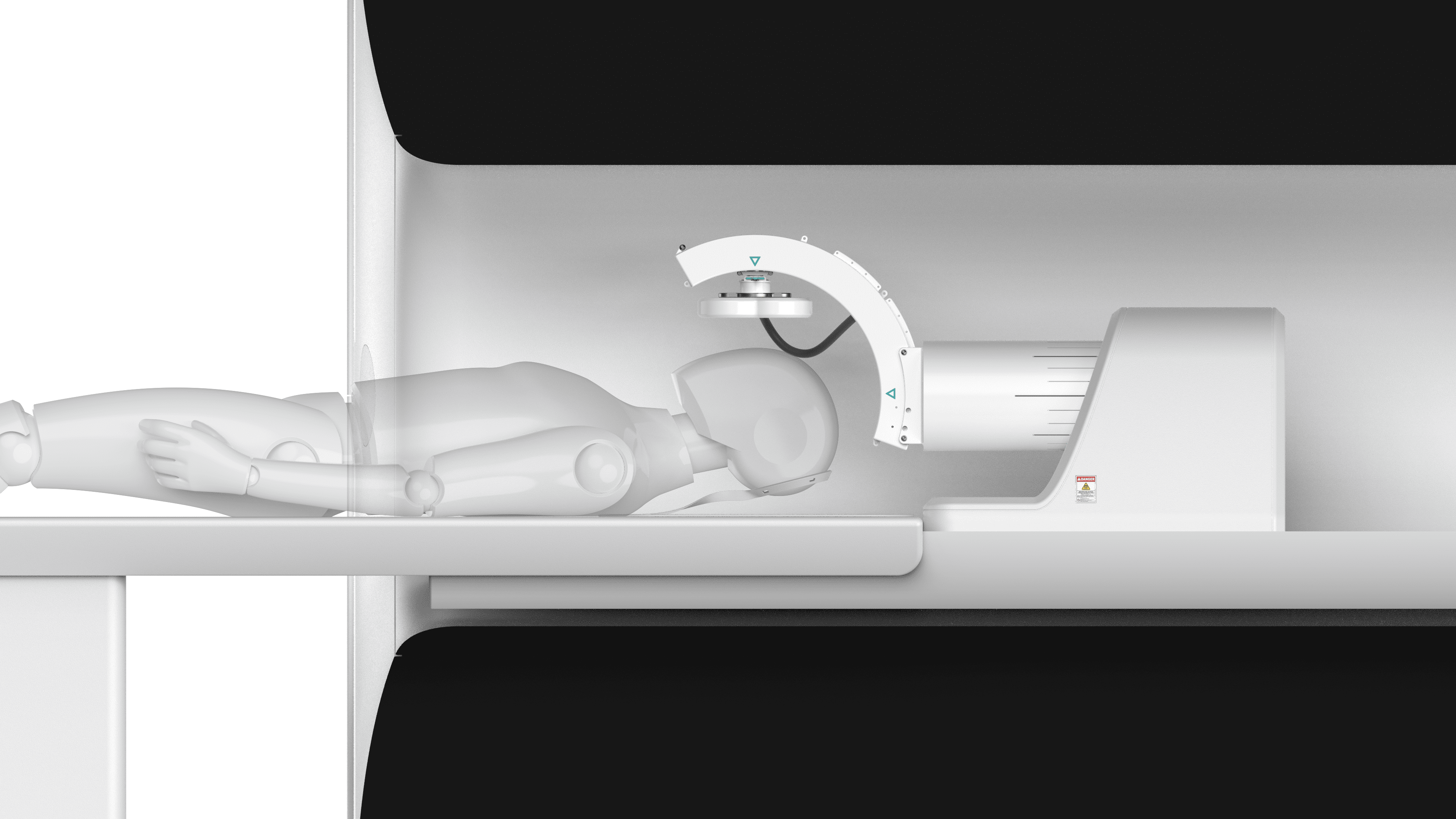

Starting with an information gathering phase, moving on to multiple prototype phases, and learning every step of the way, Mighty arrived at a final C-arm solution, engineering several never-created pieces in the process.

Normally, a device like this would be engineered using metallic materials. While early prototypes used both brass and copper for proof of concept, these are known to create residual noise inside the MRI chamber. Later iterations and the final product moved to a mix of PCA and small pieces of titanium.

The solution Mighty devised mounted an existing TMS to a C-arm, allowing the TMS to move in a hemispherical motion around the head while in the chamber. The TMS coil rode on a track inside the curved arm so that it could be placed anywhere along the head, while the head of the patient was suspended on a small platform so that the operator could position the coil underneath to treat the back of the head, if needed. The third axis of movement was the rotation or tilt of the TMS in its position to create an even more precise placement for treatment.

The 70-centimeter diameter of an MRI tube sounds roomy enough, but once you realize the head is not lying flat at the bottom of the chamber and is instead suspended roughly in the center, the challenge of movement becomes more pointed. The final design had to account for both the width of the chamber and the presence of a standard-sized human head. The diameter of the arm also needed to be thin enough to rotate on the board and allow for the TMS tilt.

A TMS coil, regardless of the manufacturer, is an extremely bulky device. Drawing on the team’s creative mechanical innovation chops, Mighty was able to design a solution that enabled the rotation of the unit—catering to multiple sizes per TMS Coil manufacturer—around the head with precise placement for effective treatment.

Movement of the TMS Coil along the arm is like a bicycle chain, but unlike a bicycle chain, rather than the gear and bearing being on the inside, it’s on the outside. This means the coil can push, pull, and rotate 360 degrees around its path, plus double back on itself in the thickness of one link without creating a bulky loop in the chain.

After multiple prototyping rounds, the final system functioned with 200 wheels that allow the chain to smoothly slide across the arc in multiple directions, with the ability to adjust tension on the fly, along the spine of the system.

There’s no understating the complexity of the assignment and the challenges the team faced. It would, for example, be easy to build the C-arm with off-the-shelf metallic parts if an MRI machine were a safe place for those parts, but it is not. The components required for Mighty’s solution did not exist in an MRI-safe form or simply did not exist at all. This meant the team had to create their solution and engineer all parts and pieces from the ground up.

With no modification or purchasing existing parts—or even using things that were already out there for inspiration—the final TMS Coil Robot beta prototype is the result of the application of raw and real invention based on need and function.